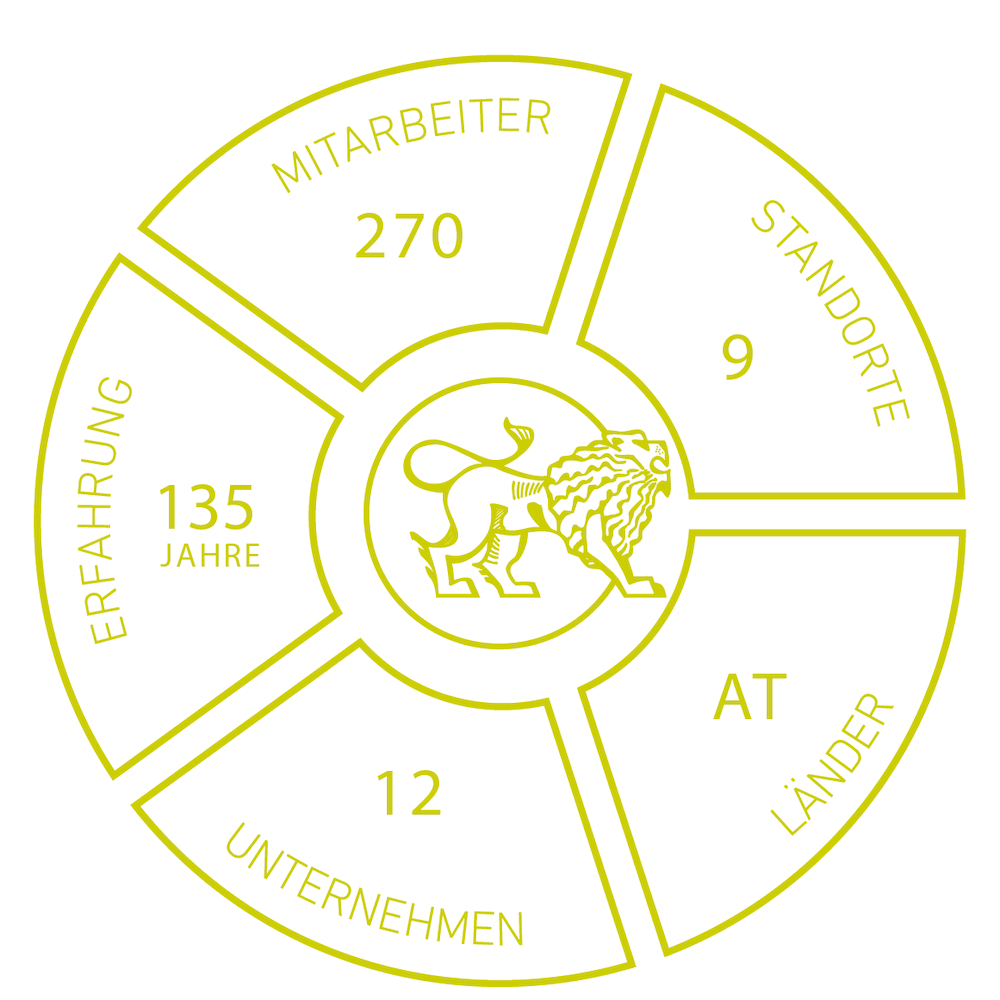

Facts zu Kirchdorfer Cement

Wir gehen nachhaltig voran!

Seit über 135 Jahren die Experten für Bindemittel und Zement: Kirchdorfer Cement steht für Innovation, saubere Produktion und Umweltverantwortung. Wir sind führend bei Ersatzbrennstoffen & Recycling und setzen Maßstäbe mit der saubersten Zementherstellung der Welt.

SPARTENLEITUNG

Joao Paulo Pereira da Silva

Kontakt

Cornelia Heim (Assistenz)

Hofmannstrasse 4

A-4560 Kirchdorf

T: +43 5 7715 200 413

F: +43 5 7715 200 466

E: cement@kirchdorfer.at

Unsere Unternehmen

Alfuma GmbH, Österreich

Ersatzbrennstoffe, Ersatzrohstoffe

Alkoven Kies GmbH & Co KG, Österreich

Zuschlagstoffe

KIAS Recycling GmbH, Österreich

Recyclingbaustoffe

Kirchdorfer Kies und Beton GmbH, Österreich

Transportbeton, Transportmöbel, Sand, Kies, Splitt

Kirchdorfer Zementwerk Hofmann Gesellschaft m.b.H., Österreich

Bindemittel, Zement

MARTINI Beton GmbH & Co. KG., Österreich

Transportbeton

Rems Beton GmbH, Österreich

Transportbeton

SRP Sekundär Rohstoff Produktion GmbH, Österreich

Aufbereitung von Gewerbeabfall

Team Asche GmbH, Österreich

Asche und Staub aus der Verbrennung von Biomasse

UWT Umwelttechnik Gmbh, Österreich

Wiederverwertung von Baurestmassen

WIBAU Containerdinest GmbH, Österreich

Containerdienst und Recycling