KAMMEL INVESTS TWO MILLION EUROS IN RESOURCE-SAVING MODERNIZATION

May 2022

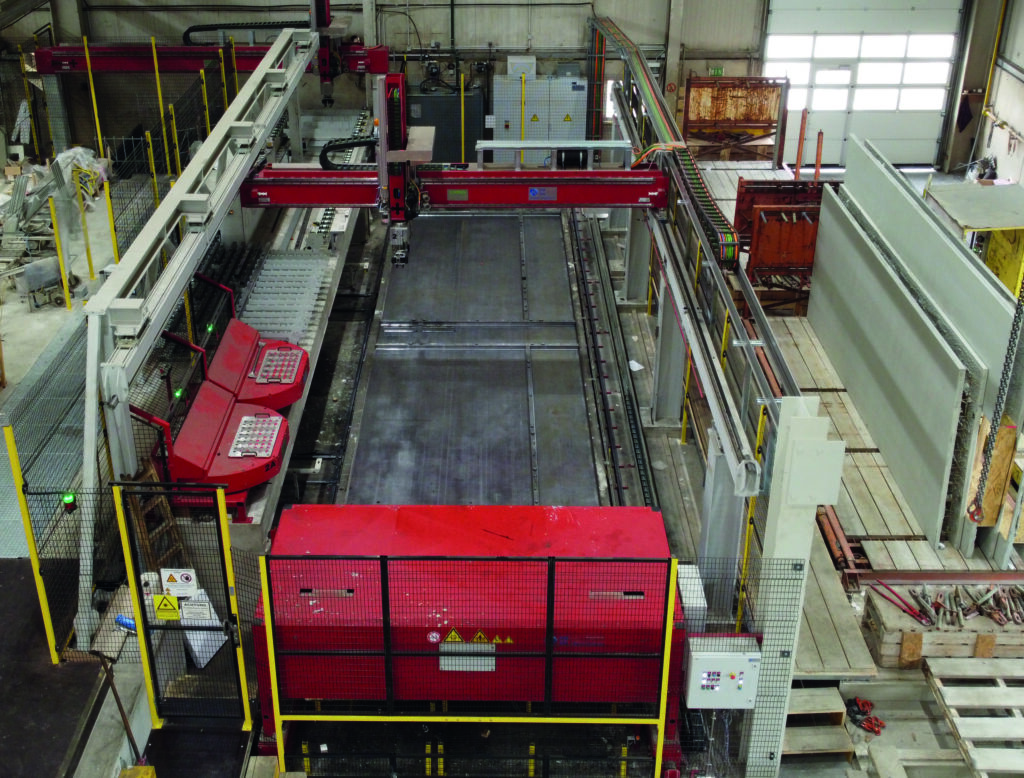

The Styrian manufacturer of prefabricated basements takes the next step in environmental protection. Following the conversion work to modernize the production hall, production at KAMMEL resumed in February.

For Managing Director Dipl. Ing. Franz Strobl, 20 years after the production hall was built, “it was necessary to renew certain components in order to meet KAMMEL’s high quality standards. The increasing demand for finished concrete products made an increase in efficiency unavoidable. With the modernizations, we are also securely positioned for the future.”

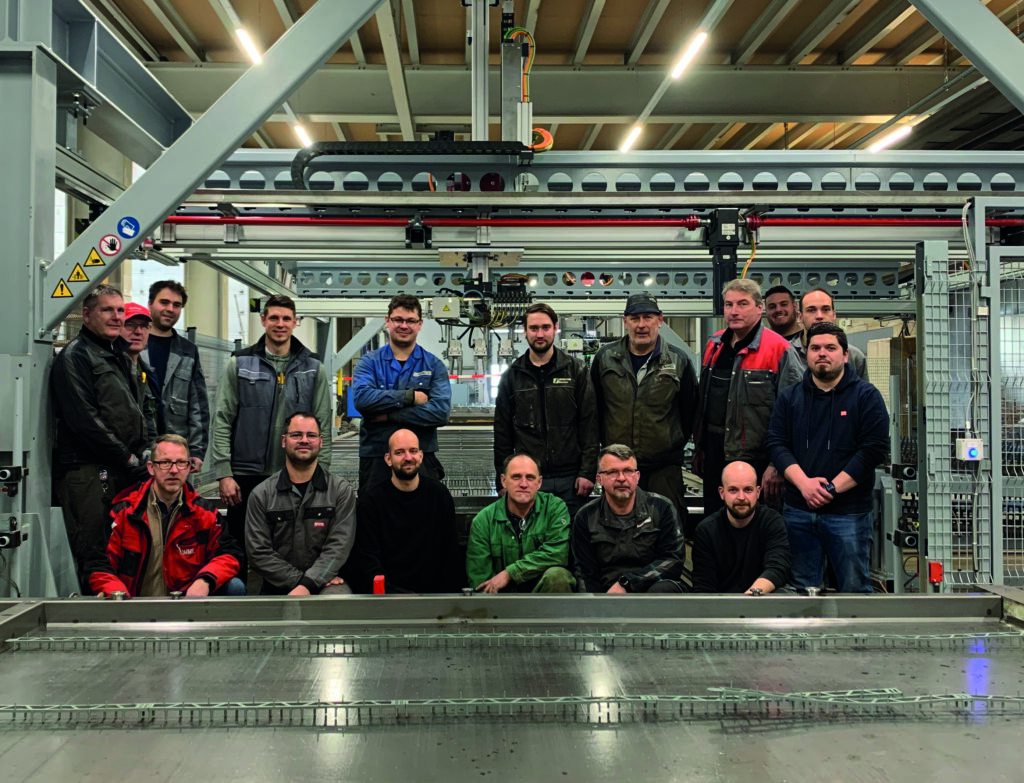

The modernization also benefits the employees. By eliminating heavy tasks such as shuttering or inserting reinforcement, individual work steps are made easier and the risk of accidents is minimized. Processes are increasingly being converted from manual to digital production without losing jobs. The safety aspect for employees was a key component of the new concept.

A shuttering and demolding robot, a reinforcement robot, a concrete spreader and an additional compaction station were also installed. There is also a turning device to enable double walls with integrated thermal insulation to be produced more efficiently and with greater insulation thickness. The control unit has also been completely updated. “In total, we have invested two million euros for further growth,” says Strobl.

Picture credits: Reproduction free of charge with attribution © Kirchdorfer